Machines without protective cover for laser

Fiber laser cutters are suitable for cutting carbon steel, stainless steel, aluminum, galvanized, as well as copper plates. Single-table open Fiber laser cutting machines are often used to process thinner plates, but sometimes the extreme length of the plates requires the omission of the protective cover. Smaller open machines often implement a high-tech manufacturing plant with little investment. The small table size and the open space do not mean a reduction in technological standards. The linear units, the drive and the CAD-CAM systems represent the appropriate industrial quality to match state-of-the-art laser technology. The standard table sizes provide a work area of 900*1300, 1300*2500, 3000*1500 mm. In the case of individual large machines, the width of the long plates that can be processed is 1,500 mm or more, while the length of the sheets can be up to 12 m. Laser power is usually less than 2 kW in the case of smaller table sizes. An important accesory of laser machines is the smoke filter unit, which, in addition to health protection, also plays a significant role in saving energy.

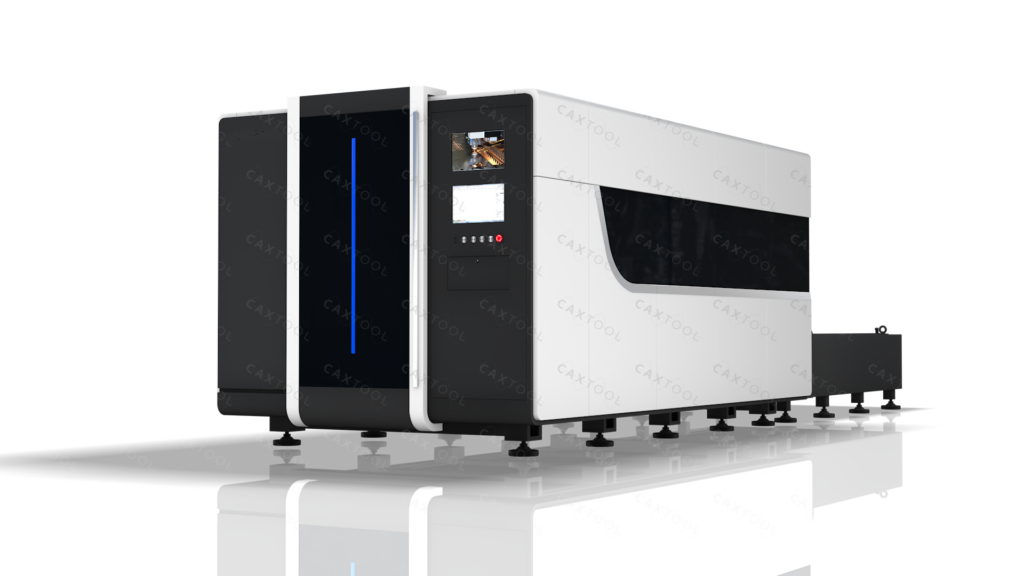

Single-table laser machines with protective cover for laser

Fiber laser cutters are suitable for cutting carbon steel, stainless steel, aluminum, galvanized, as well as copper plates. Single-table laser machines – with no retractable interchangeable table -, usually with a work area of 1500*3000 mm or less, with a laser power of less than 2 kW can be considered as a separate group. The protective cover can be important from a safety point of view regarding the efficiency of smoke extraction. The disadvantage is that it is difficult to place the plate into the work area. It offers an excellent solution for educational purposes, custom production and processing thin plates. The standard table sizes provide a work area of 900*1300, 1300*2500 or 3000*1500 mm. The linear units, the drive and the CAD-CAM systems represent the appropriate industrial quality to match state-of-the-art laser technology.

Laser machines with interchangeable table and protective cover for laser

Fiber laser cutters are suitable for cutting carbon steel, stainless steel, aluminum, galvanized, as well as copper plates. The majority of Fiber laser cutting machines built specifically for operation during one, two or three shifts fall into this category. During its operation, the laser head performs its task in an enclosed space, while next to or behind the work area, the interchangeable table can be used to remove the finished products and place the new plate. In the work area, the two tables swap places after completing the laser cutting task. The standard table size is 1500*3000 mm, the standard laser power is between 1 and 6 kW, but the technology can modify these value limits. An important accesory of laser machines is the smoke filter unit, which, in addition to health protection, also plays a significant role in saving energy. The most important elements of laser machines include, but are not limited to, the laser head (Raytools, Precitec ..), the laser source (IPG, Raycus, JPT ..), the drive (Yaskawa, Nidec, Schneider ..), the machine frame, the software. Caxtool Ltd. helps with the selection, installation, set-up and servicing of the laser machine suitable for the expected task and use.

KIMLA Laser fiber cutter

KIMLA laser fiber with linear drives, enables quick and efficient cutting of any shape out of sheet metal. Our lasers are extremely high speed up to 5 m/s and fast acceleration. This power combined with a high resolution measurement system we achive extraordinary efficienvy and cutting accuracy.